Flow Chemistry

In close collaboration with the pharmaceutical and fine chemical industry Chemtrix BV has developed a complete, easy to scale product portfolio for continuous processing from laboratory to industrial production scale.

In close collaboration with the pharmaceutical & fine chemical industry Chemtrix BV has developed a complete, easy to scale product portfolio for continuous processing from laboratory to industrial production scale. Our laboratory systems (Labtrix GramFlow & KiloFlow) are based on glass reactors, selected for chemical compatibility, material awareness of the synthetic chemist & optical transparency. Our systems for continuous production on an industrial scale, Protrix & Plantrix, are based on 3M silicon carbide reactors selected for their superior chemical flexibility & high corrosion resistance.

In Flow Chemistry, two or more reagents are continuously pumped into a flow reactor where they are mixed & then reacted under thermal control.

Advantages of Flow Chemistry

Flow Chemistry has some important advantages; Mixing can be achieved within a few seconds & the reaction temperature can rise above the boiling point of the solvent, resulting in faster reactions. Flow Chemistry makes excellent reaction selectivity possible. The rapid diffusion mixing avoids the problems encountered in batch reactors. The high surface / volume ratio (1000x larger than a batch reactor) enables heating or cooling almost immediately & therefore has the ultimate temperature control, resulting in cleaner products.

Flow Chemistry allows only a small amount of hazardous intermediates that are formed at any time. The large surface also ensures excellent control of exothermic reactions with the help of Flow Chemistry, resulting in safer reactions. Flow Chemistry with automation enables the rapid variation of reaction conditions on a μl scale. Parameters such as reaction time, temperature, flow, pumped volumes & pressure can all be varied quickly. One reaction can follow the other, separated by a solvent, whereby the previous reaction is cleaned, allowing a quick reaction to be optimized. Scale enlargement problems are minimized by maintaining excellent mixing & heat transfer. Higher flow rates & correspondingly larger reactors can be used to easily produce quantities of kilograms or tons by scale using Flow Chemistry.

Flow Reactors

A Flow Reactor (or Micro Reactor) is a device in which chemical reactions take place in micro channels. The Micro Reactor is usually a continuous flow reactor (contrast with/to a batch reactor). Micro Reactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed & yield, safety, reliability, scalability, on-site/on-demand production, & a much finer degree of process control.

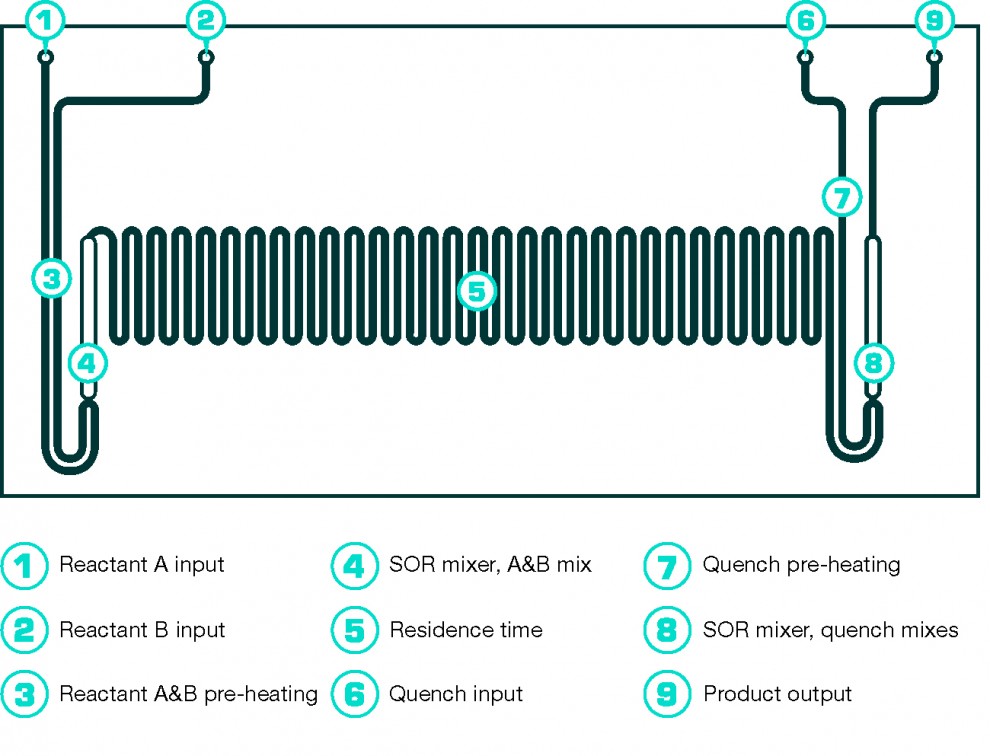

Chemtrix Micro Reactors have up to 3 reagent inputs, suitable for A+B or A+B+C reactions. After the reactants are pumped into the Micro Reactor, the reactants are pre-heated before going into the SOR-mixer where they mix. After mixing, the fluids enter the residence time channels in which the reaction takes place. Depending on the speed of the reaction, different Micro Reactors are available with different volumes. To stop the reaction in the Micro Reactor, a quench can be pumped in. Before entering the second SOR mixer, the quench solvent is pre-heated. Chemtrix BV supply a series of standard glass Micro Reactors, suitable for reaction screening at the mg to g scale. The Micro Reactors differ in volume & number of fluidic input connections.

Do you want to know more about Flow Chemistry or Flow Reactors? Then visit our Download Center for reading more documentation.