History

Started in 2008, Chemtrix BV continues to follow our founding mission of Scalable Flow Chemistry. Working closely with Academia & Industry, Chemtrix BV contribute to the changing face of chemical process development & implementation. Delivering hardware & services to increase process safety, reduce operating costs & implement new chemical possibilities at an industrial scale.

-

Where it all Started!

Research

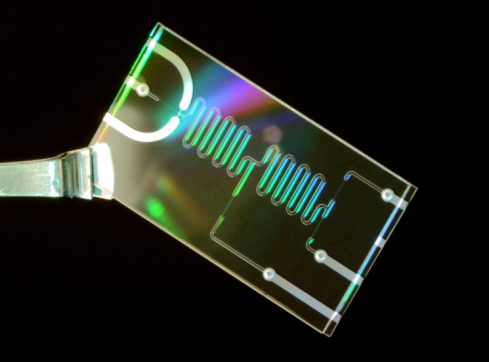

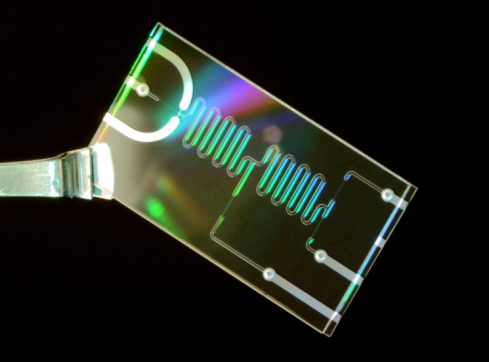

It all started with a research project, sponsored by Novartis (Basel, CH), to look into the use of micro reactors for the performance of common synthetic transformations! With devices fabricated by hand at The University of Hull, each reaction system was bespoke. We soon realised that common elements were needed, from which systems could be built, to address the broad synthetic demands! The early years were spent evaluating those synthetic transformations that could benefit from process intensification & defining suitable wetted materials for robust operation.

-

Strategic Partnership with Lionix BV

Partnership

Following an introduction to Dr Hans van den Vlekkert (Lionix BV, NL) by Mr Chris Lamaison (Cambridge Resolution, UK), researchers at The University of Hull started to use high quality reactors manufactured by Lionix BV. Under the direction of Prof. Paul Watts, this was the Group's first experience of producing large fabrication runs of micro reactors - critically demonstrating repeatability between devices!

-

Joint Venture Forms Chemtrix Ltd.

Company Founded

At the end of 2005, Chemtrix Ltd. was founded as a Joint Venture between Lionix BV (NL) & The University of Hull (UK), with the goal of developing continuous flow systems & services for pharmaceutical & fine chemical applications.

-

Chemtrix BV Founded

Company Founded

Chemtrix BV was founded on the 28th March 2008 & headquartered on the Brightlands Chemelot Campus (Geleen, NL) - product development started & launch Customers were identified. Later in the year, an investment round brought in new investors.

-

Labtrix S1 - Product Launch

Product Launch

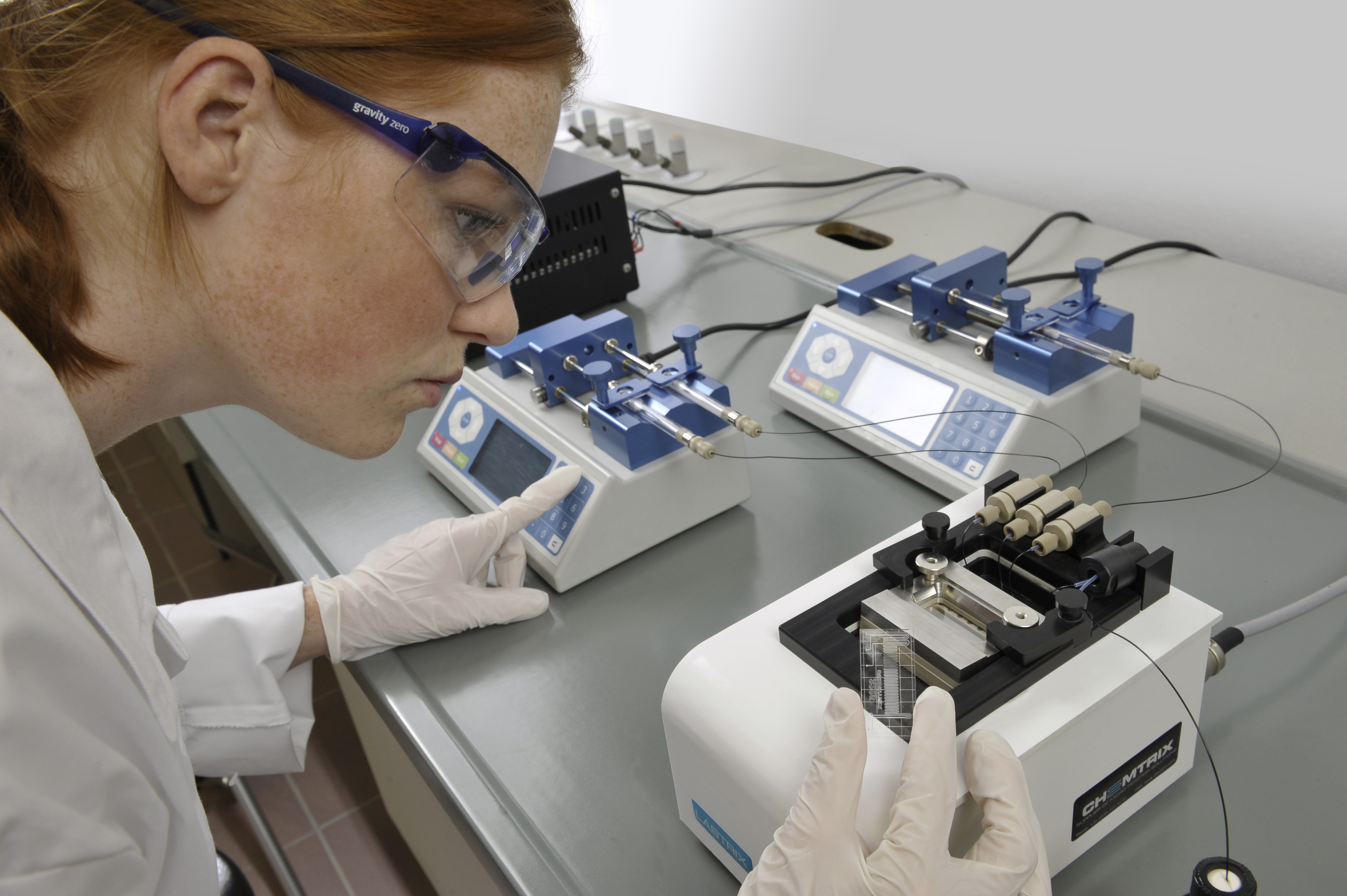

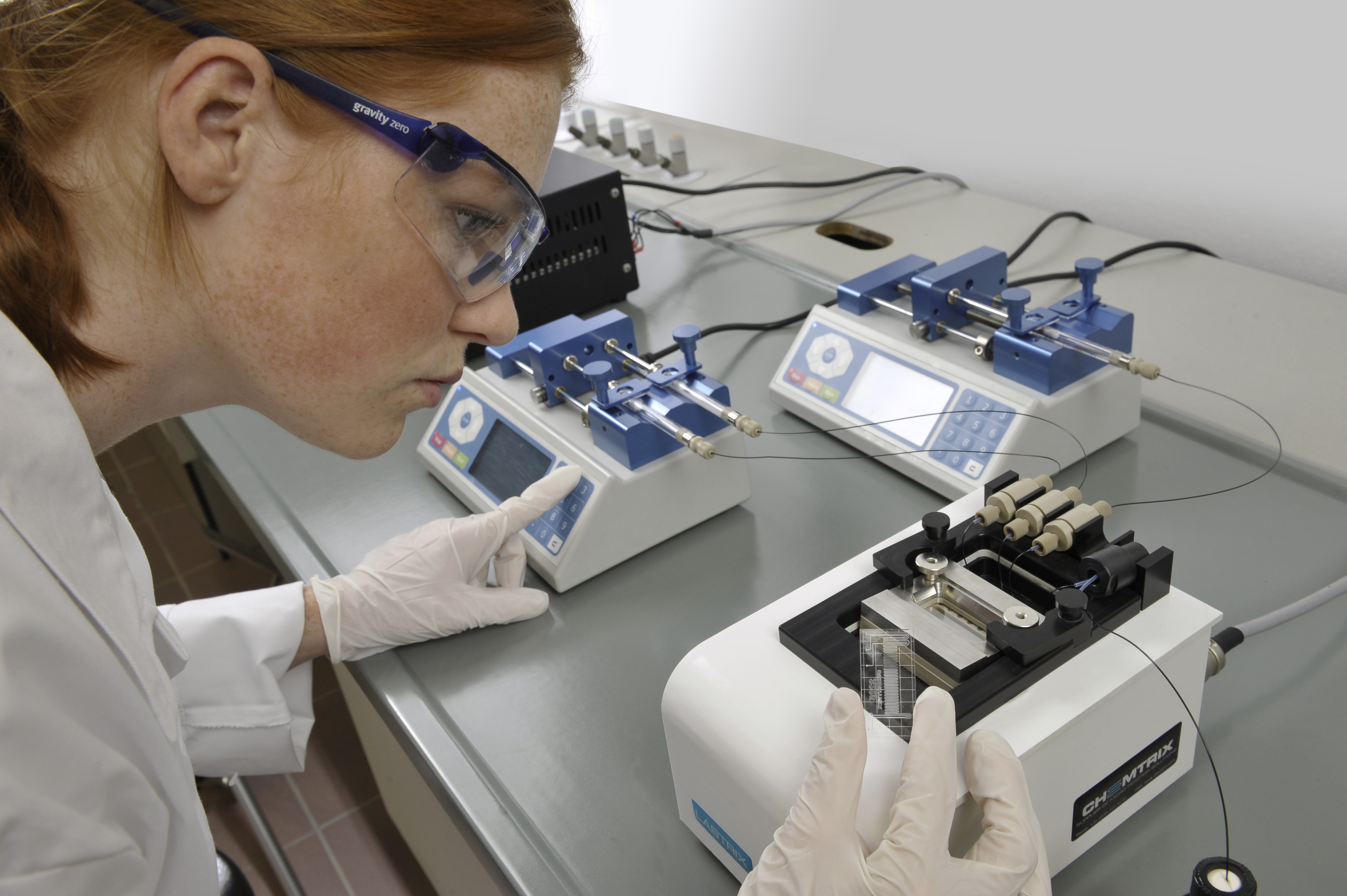

In June 2009 we launched the first product, Labtrix® S1. An automated 'plug & play' continuous reaction system for lab-based screening & method development. Using glass micro reactors, the automated system can be run unattended & perform detailed reaction optimisation using mg-quantities of material.

-

Labtrix Start - Product Launch

Product Launch

Building on the success of last year's Labtrix® S1 platform release, early 2010 saw us launch Labtrix® Start. Based on the same glass micro reactors, the manual platform enables users to explore novel process conditions at the lab-scale, ideal for education & training.

-

KiloFlow - Product Launch

Product Launch

Working with launch Customers DSM (Geleen, NL) & Janssen Pharmaceutica (Beerse, BE), KiloFlow® was developed to rapidly scale from mg-scale screening through to multi-kg production.

-

Plantrix MR260 - Product Launch

Product Launch

In 2012 we expanded our Scalable Flow Chemistry product line to incorporate Plantrix® modular ceramic flow reactors, manufactured from 3M™ silicon carbide. Suitable for the performance of reactions at the tonne scale, the use of silicon carbide enables processes involving aggressive reagents & challenging conditions to be safely performed.

-

Opening of Zhejiang University of Technology Demo Centre!

Demo Facility

We opened our first joint laboratory in China at the School of Pharmacy, Zhejiang University in July 2012! With Labtrix® Start & Plantrix® MR260 we can develop & demonstrate continuous flow processes under the expert guidance of Prof. Xia & our colleagues at Shenzhen E-zheng Technology Co. Ltd.

-

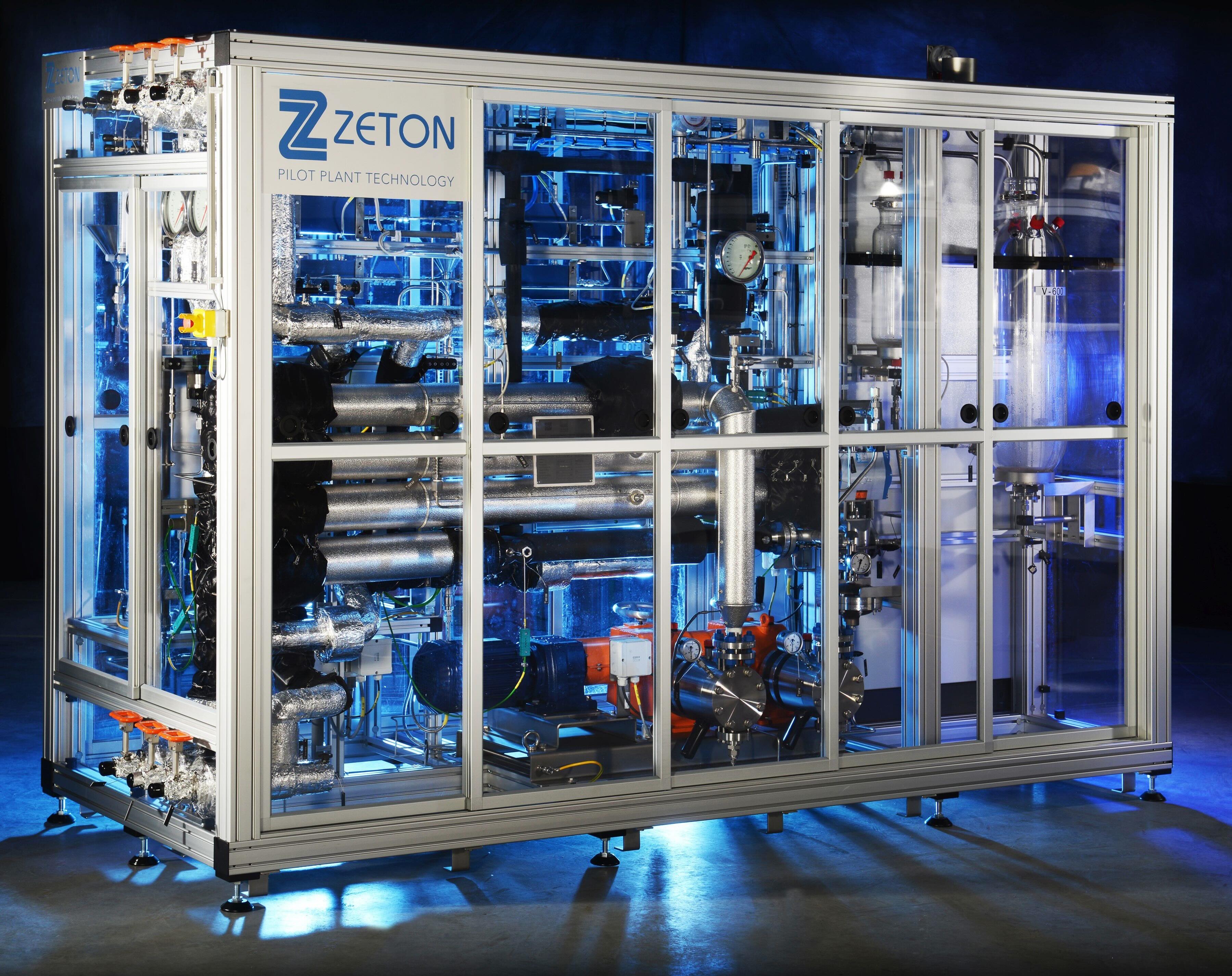

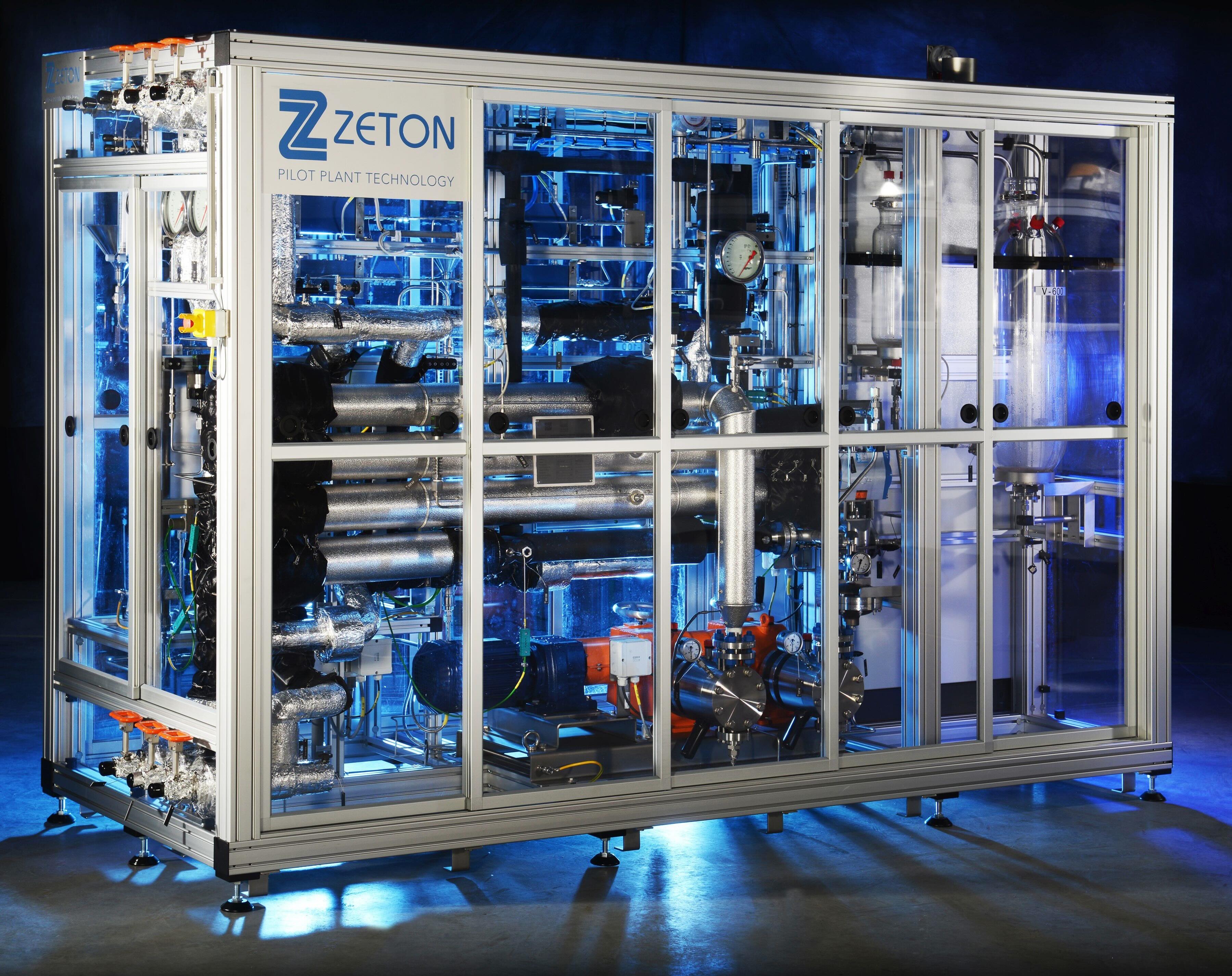

CoRIAC Project Wrap-up

Funded Project

Demonstration of Continuous Reactors with In-line Analytics for Fine Chemicals Production' was a project that ran from 2010 to 2014. Working with project partners; DSM, ISPT, ESK, Bronkhorst, Procter & Gamble, Mettler Toledo, Zeton, TU/e & Koning & Hartman we benchmarked & demonstrated flow reactor technologies across specialty, commodity & pharmaceutical applications. Modularisation & flexibility of hardware towards different unit operations was a key take home message.

-

Plantrix MR555 Launches at ACHEMA 2015!

ACHEMA

Co-exhibiting with our Strategic Partner 3M Technical Ceramics GmbH, we introduced Plantrix® MR555 at ACHEMA 2015! Our latest development in our scalable flow reactor portfolio, affording material production at the 1000's tonne/annum scale.

-

Protrix - Product Launch

Product Launch

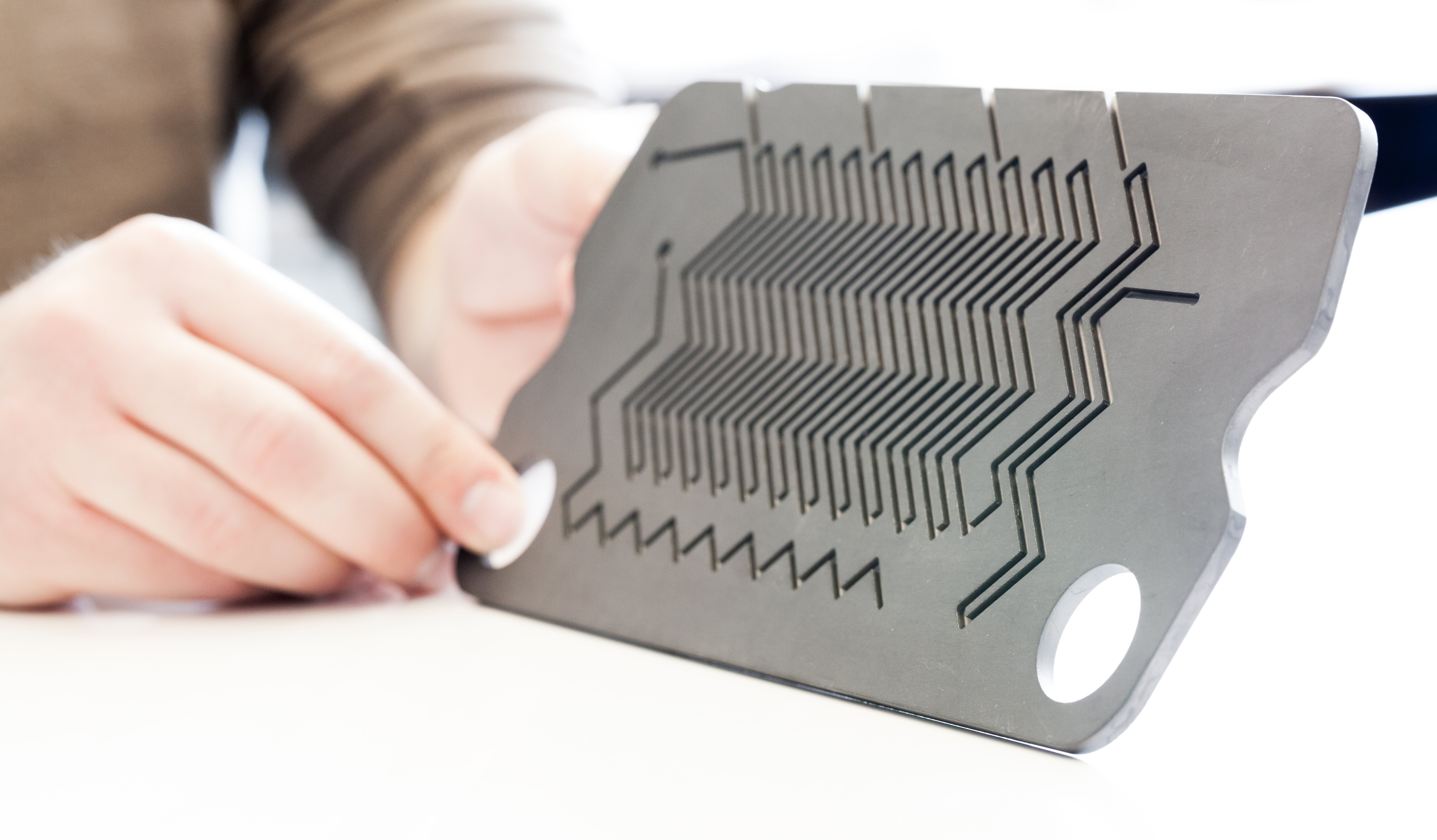

Protrix® is our modular, lab-scale ceramic (SiC) flow reactor, designed for chemical process development & small-scale production. Its modular set-up is flexible to changing process demands & its scale-factor (x340) to Plantrix® MR555 gives a clear path from lab to production.

-

Hebei University Joint Laboratory

Demo Facility

On the 23rd June 2017, we held the opening ceremony for the 'Micro Reactor Technology Cooperation Laboratory' established at Hebei University of Technology (Tianjin, CN) with our partner Shenzhen E-zheng Technology Co. Ltd.. With Labtrix® Start, KiloFlow® & Protrix® flow reactors available, researchers can develop scalable flow processes & perform valuable training for the next generation!

-

CCFlow Consortium Kick-off!

Demo Facility

In July 2017, Chemtrix BV became part of the Austrian Research Promotion Agency's K-Project CCFLOW 'Centre for Continuous Flow Synthesis & Processing', directed by Prof. Oliver Kappe (University of Graz, AT). With a strategic objective to integrate, strengthen & advance existing knowledge in the area of continuous processing / flow chemistry, the project focusses on process simplification, intensification & integration. This industry-academia consortium enables Chemtrix to have a Protrix® silicon carbide flow reactor at CCFLOW!

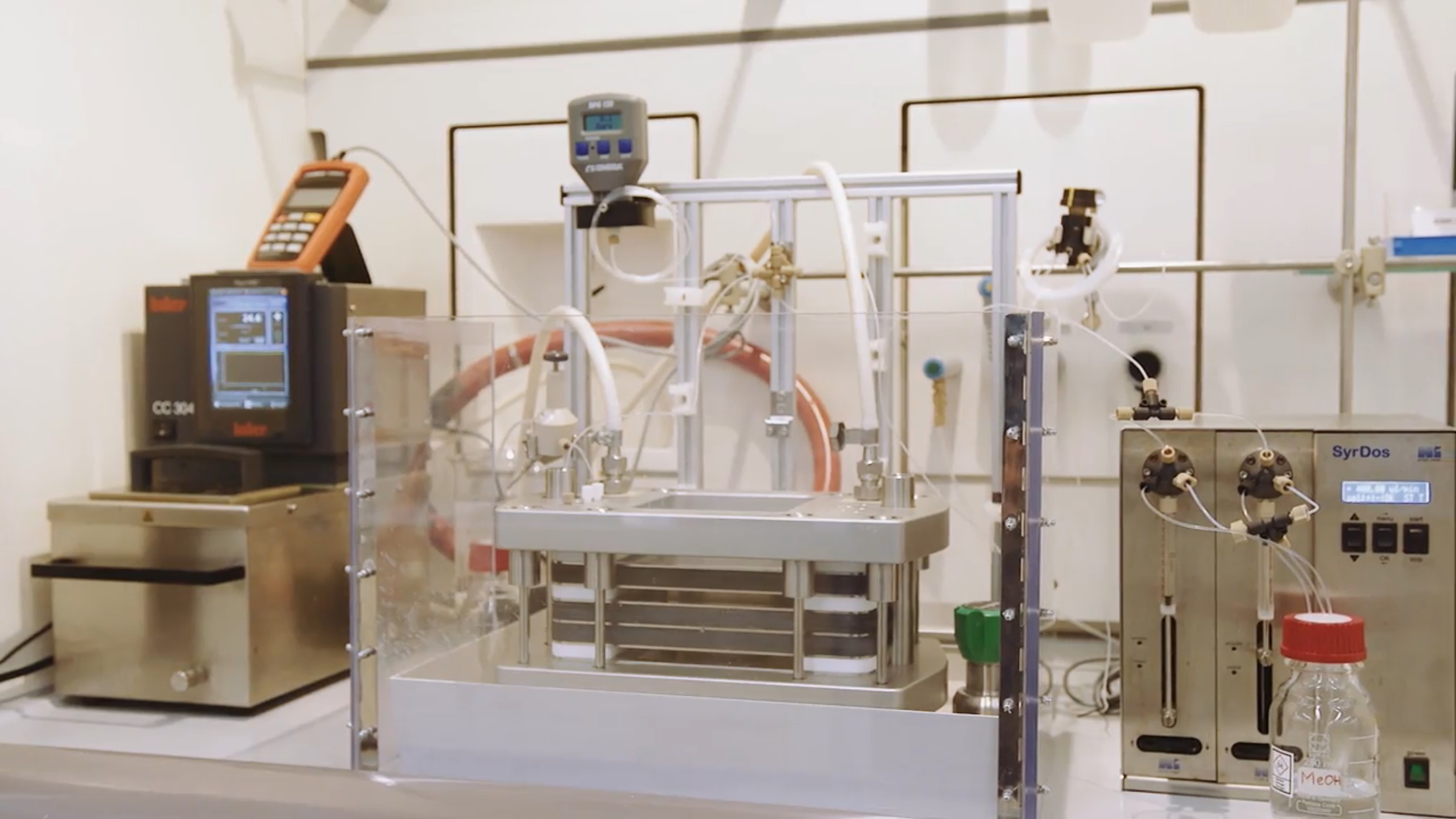

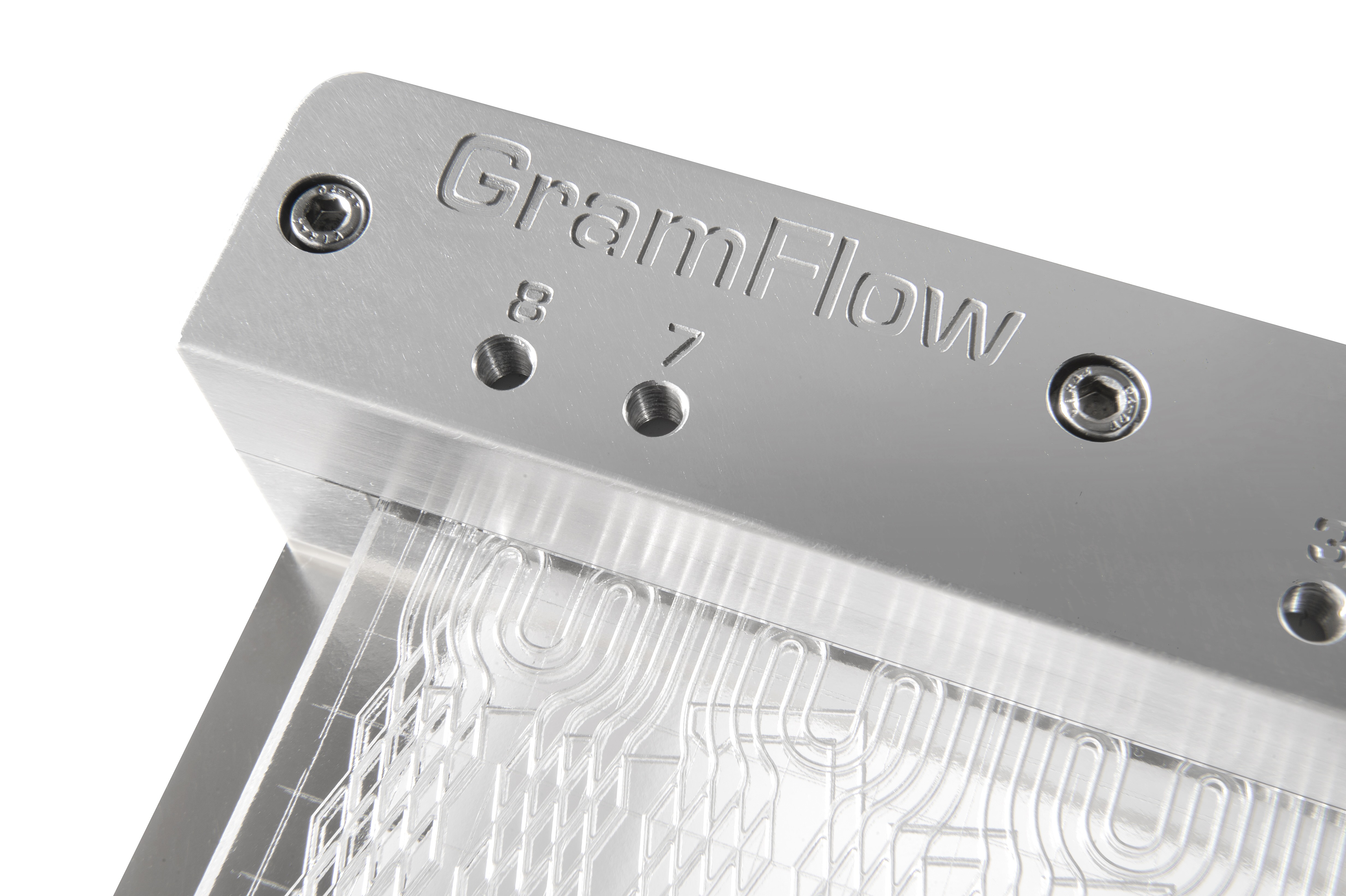

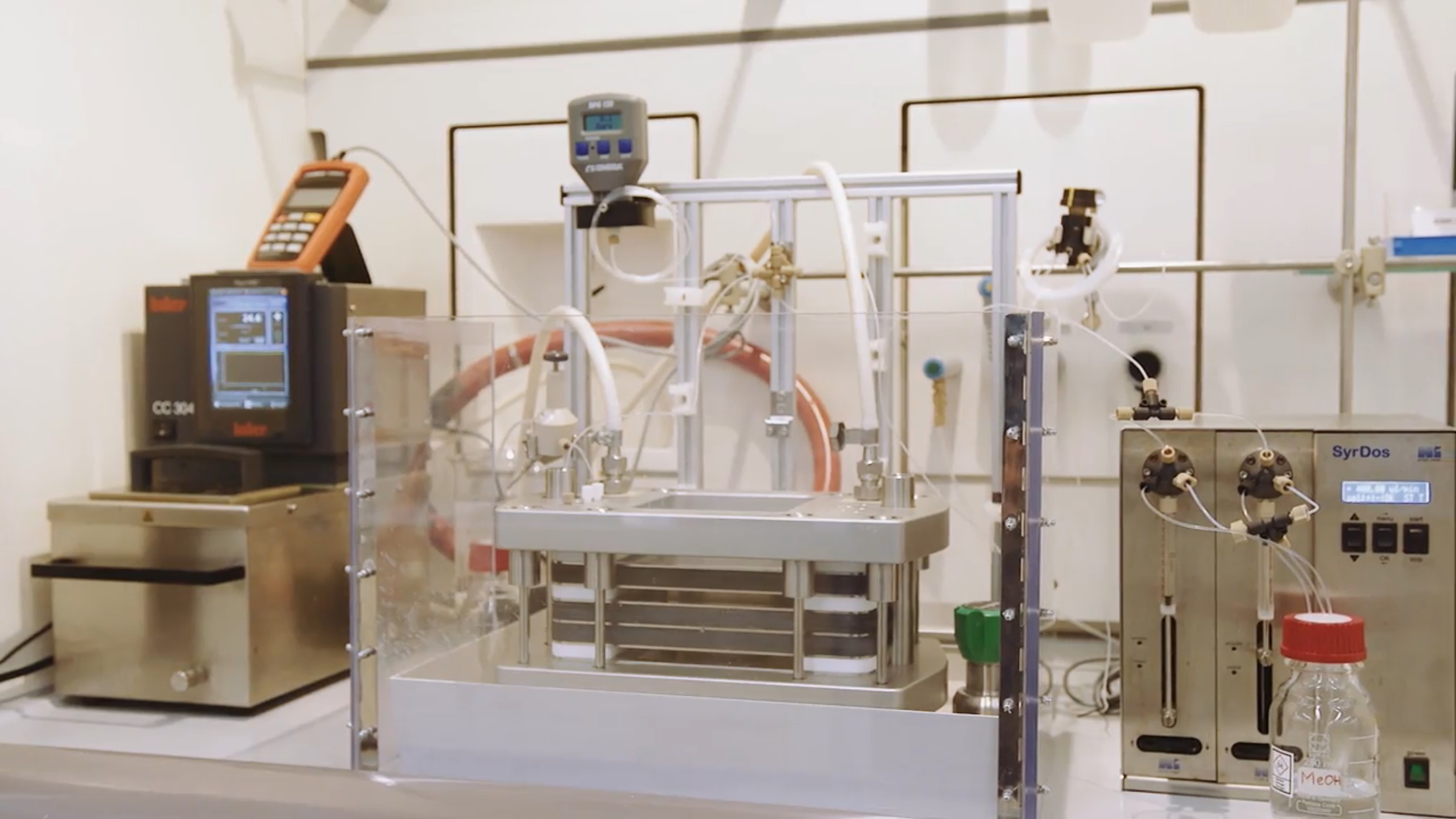

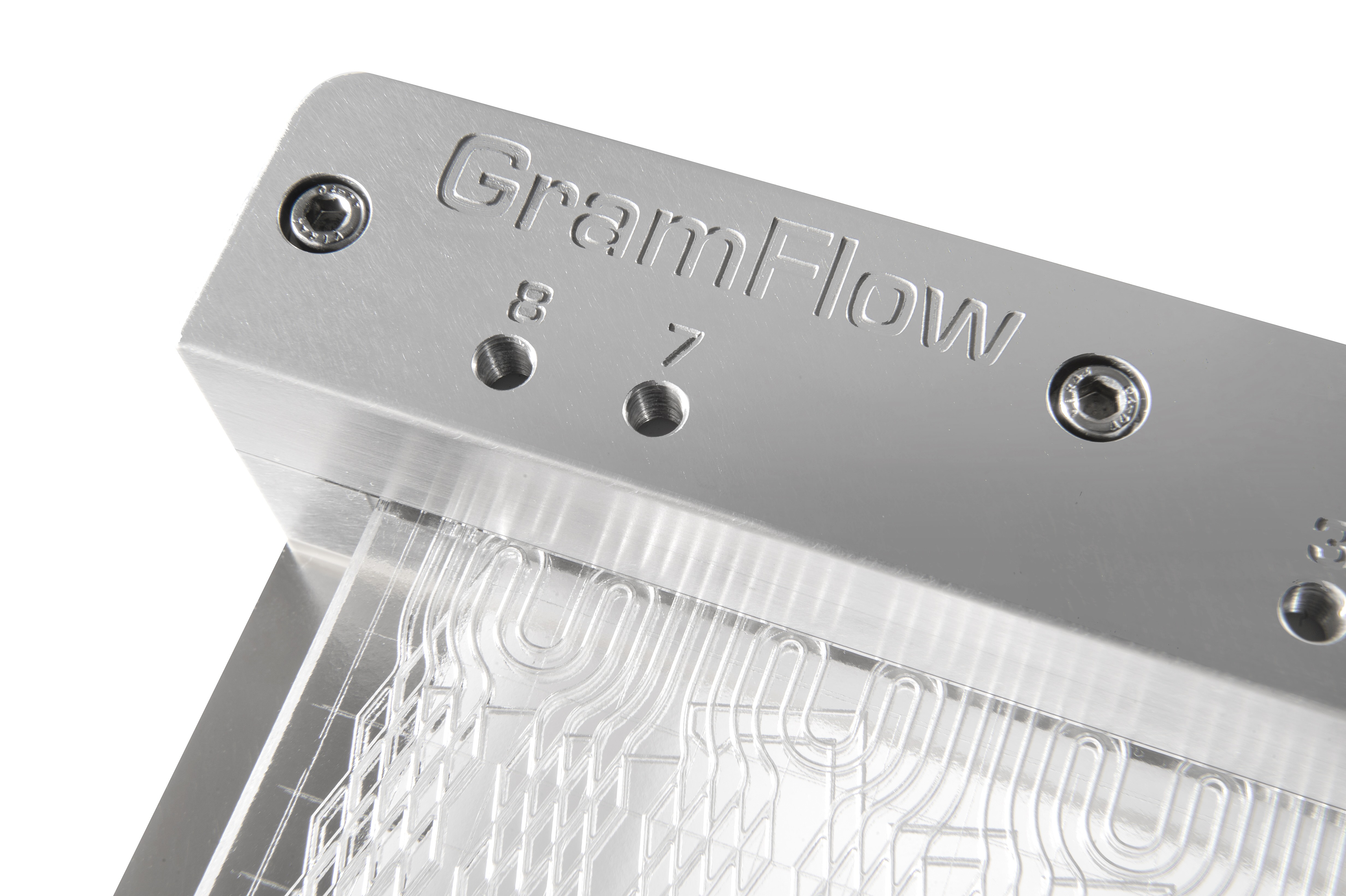

GramFlow - Product Launch

Product Launch

July 2017 saw the introduction of GramFlow®, our single module glass flow reactor developed for reaction screening & small volume material production. Employing the same integrated heat exchange as KiloFlow®, GramFlow® enables thermally demanding processes to be controlled.

-

Fudan University Joint Laboratory

Demo Facility

Fudan University, Chemtrix & E-zheng Joint Laboratory for Continuous Reactor Technology opened in China, enabling local research to be performed using Labtrix® Start, GramFlow® & Protrix® flow reactors.

1st Flow Chemistry Pavilion at ACHEMA 2018

ACHEMA

11-15th June 2018 saw us arrange the first Flow Chemistry Pavilion at ACHEMA. With a five-day exhibition & a one-day dedicated symposium featuring Industrial Case Studies, this event enabled the Flow Chemistry Community to come together & become a destination at this globally renowned tradeshow. The event was a huge success & will be repeated at ACHEMA 21.

-

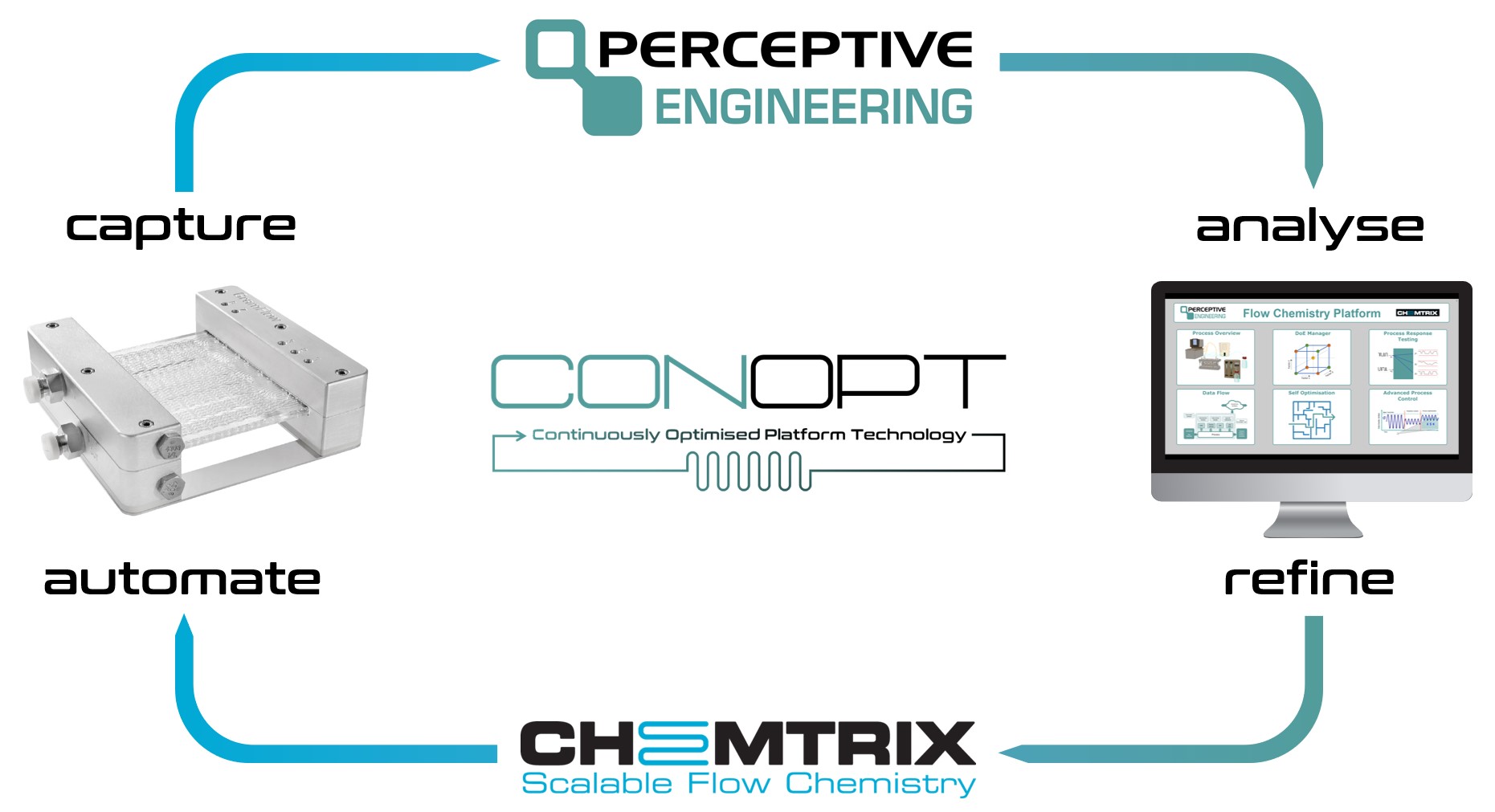

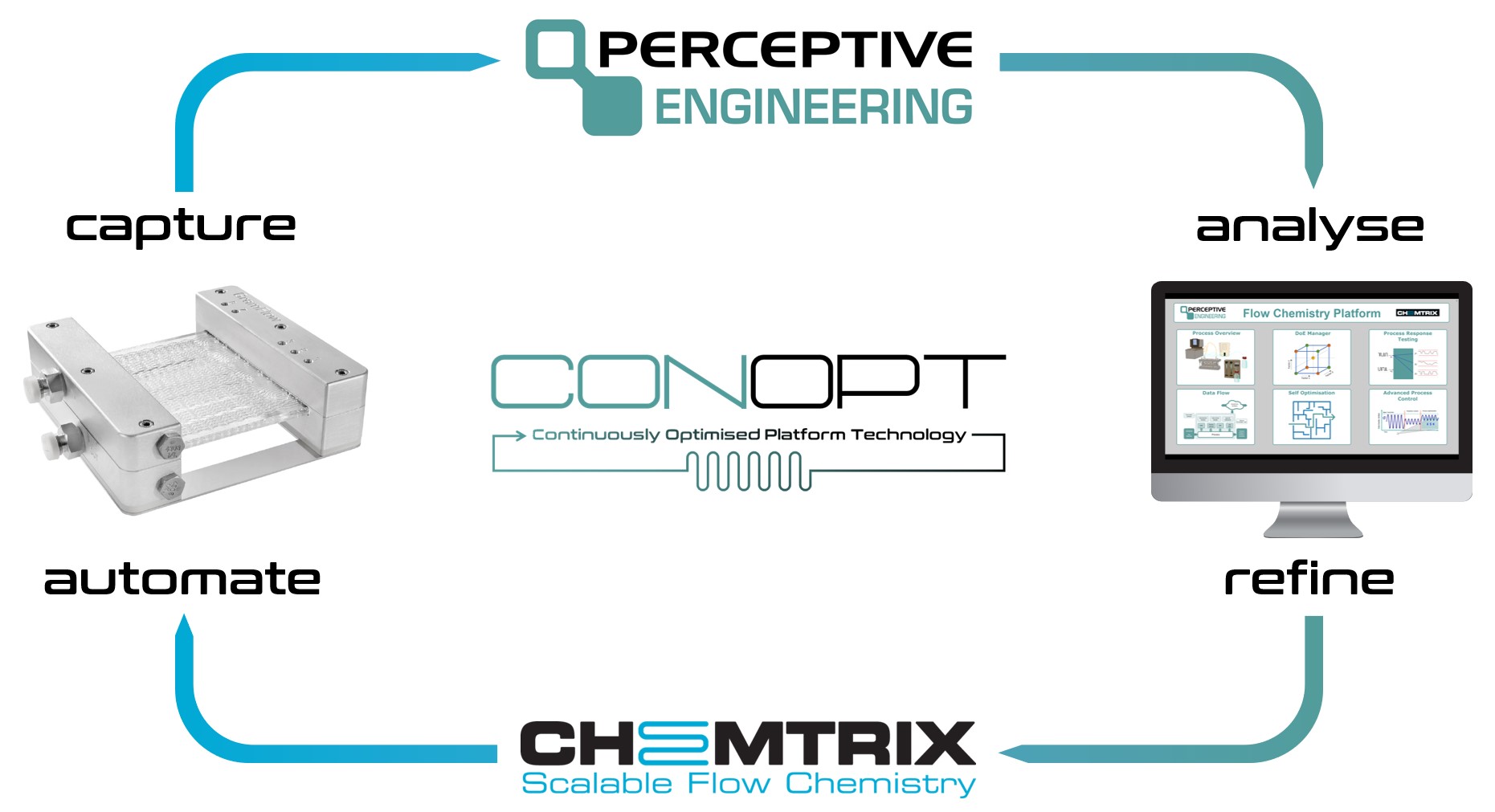

GlobalStars award with Perceptive Engineering!

Project

On March 31st 2020, we entered into a collaboration project with Perceptive Engineering (SG) & a multinational pharmaceutical Company to deliver a solution for the production of high-value / low-volume pharmaceuticals using small-scale, flexible continuous manufacturing. This EUREKA project will allow us to combine our expertise to develop a platform solution applicable to pharmaceutical, agrochemical & specialty chemical production.

Jun 2000

Where it all Started!

Research

It all started with a research project, sponsored by Novartis (Basel, CH), to look into the use of micro reactors for the performance of common synthetic transformations! With devices fabricated by hand at The University of Hull, each reaction system was bespoke. We soon realised that common elements were needed, from which systems could be built, to address the broad synthetic demands! The early years were spent evaluating those synthetic transformations that could benefit from process intensification & defining suitable wetted materials for robust operation.

Apr 2003

Strategic Partnership with Lionix BV

Partnership

Following an introduction to Dr Hans van den Vlekkert (Lionix BV, NL) by Mr Chris Lamaison (Cambridge Resolution, UK), researchers at The University of Hull started to use high quality reactors manufactured by Lionix BV. Under the direction of Prof. Paul Watts, this was the Group's first experience of producing large fabrication runs of micro reactors - critically demonstrating repeatability between devices!

Dec 2005

Joint Venture Forms Chemtrix Ltd.

Company Founded

At the end of 2005, Chemtrix Ltd. was founded as a Joint Venture between Lionix BV (NL) & The University of Hull (UK), with the goal of developing continuous flow systems & services for pharmaceutical & fine chemical applications.

Mar 2008

Chemtrix BV Founded

Company Founded

Chemtrix BV was founded on the 28th March 2008 & headquartered on the Brightlands Chemelot Campus (Geleen, NL) - product development started & launch Customers were identified. Later in the year, an investment round brought in new investors.

Jun 2009

Labtrix S1 - Product Launch

Product Launch

In June 2009 we launched the first product, Labtrix® S1. An automated 'plug & play' continuous reaction system for lab-based screening & method development. Using glass micro reactors, the automated system can be run unattended & perform detailed reaction optimisation using mg-quantities of material.

Feb 2010

Labtrix Start - Product Launch

Product Launch

Building on the success of last year's Labtrix® S1 platform release, early 2010 saw us launch Labtrix® Start. Based on the same glass micro reactors, the manual platform enables users to explore novel process conditions at the lab-scale, ideal for education & training.

Oct 2011

KiloFlow - Product Launch

Product Launch

Working with launch Customers DSM (Geleen, NL) & Janssen Pharmaceutica (Beerse, BE), KiloFlow® was developed to rapidly scale from mg-scale screening through to multi-kg production.

Jun 2012

Plantrix MR260 - Product Launch

Product Launch

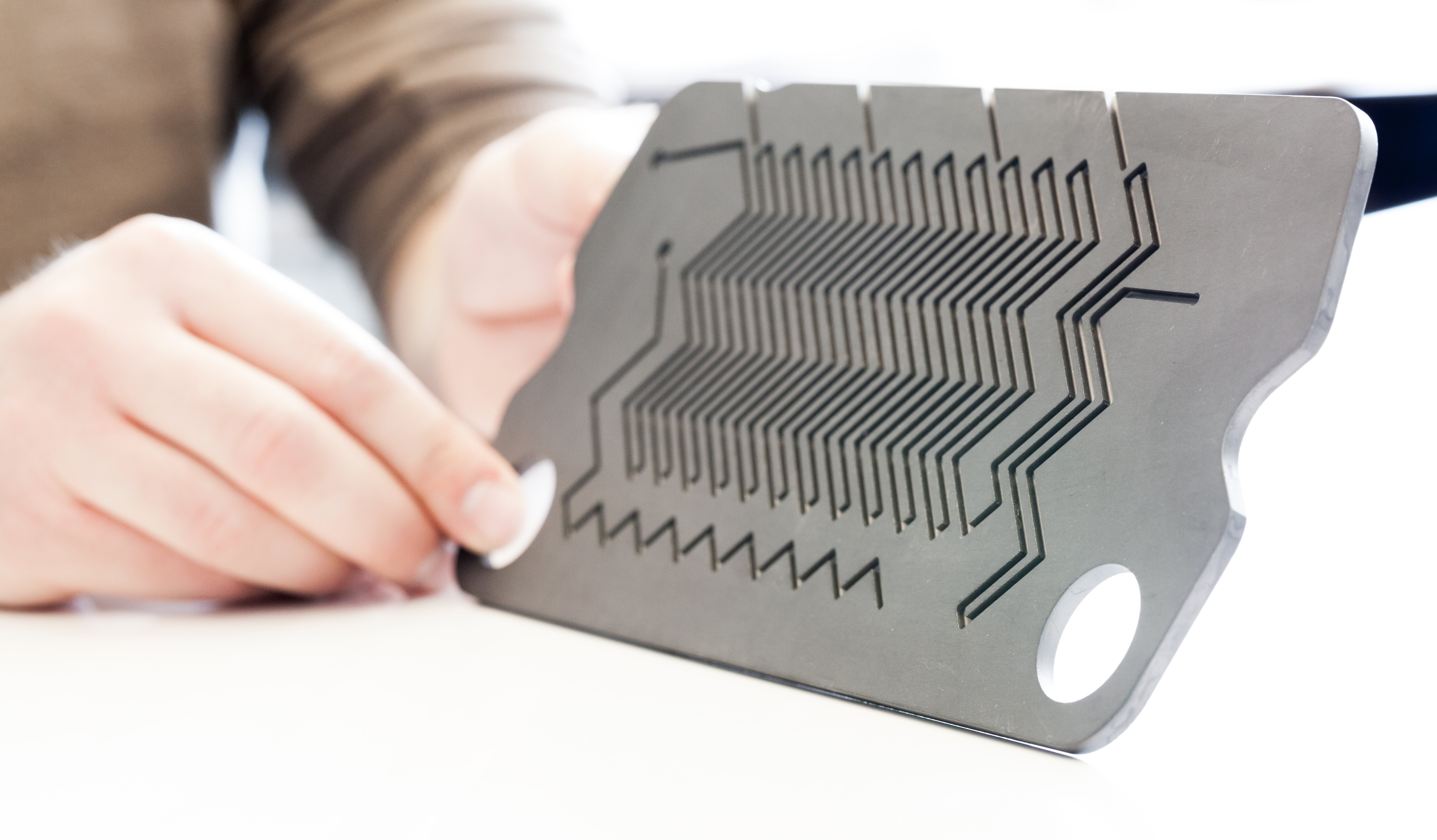

In 2012 we expanded our Scalable Flow Chemistry product line to incorporate Plantrix® modular ceramic flow reactors, manufactured from 3M™ silicon carbide. Suitable for the performance of reactions at the tonne scale, the use of silicon carbide enables processes involving aggressive reagents & challenging conditions to be safely performed.

Jul 2012

Opening of Zhejiang University of Technology Demo Centre!

Demo Facility

We opened our first joint laboratory in China at the School of Pharmacy, Zhejiang University in July 2012! With Labtrix® Start & Plantrix® MR260 we can develop & demonstrate continuous flow processes under the expert guidance of Prof. Xia & our colleagues at Shenzhen E-zheng Technology Co. Ltd.

Dec 2014

CoRIAC Project Wrap-up

Funded Project

Demonstration of Continuous Reactors with In-line Analytics for Fine Chemicals Production' was a project that ran from 2010 to 2014. Working with project partners; DSM, ISPT, ESK, Bronkhorst, Procter & Gamble, Mettler Toledo, Zeton, TU/e & Koning & Hartman we benchmarked & demonstrated flow reactor technologies across specialty, commodity & pharmaceutical applications. Modularisation & flexibility of hardware towards different unit operations was a key take home message.

Jun 2015

Plantrix MR555 Launches at ACHEMA 2015!

ACHEMA

Co-exhibiting with our Strategic Partner 3M Technical Ceramics GmbH, we introduced Plantrix® MR555 at ACHEMA 2015! Our latest development in our scalable flow reactor portfolio, affording material production at the 1000's tonne/annum scale.

Jul 2016

Protrix - Product Launch

Product Launch

Protrix® is our modular, lab-scale ceramic (SiC) flow reactor, designed for chemical process development & small-scale production. Its modular set-up is flexible to changing process demands & its scale-factor (x340) to Plantrix® MR555 gives a clear path from lab to production.

Jun 2017

Hebei University Joint Laboratory

Demo Facility

On the 23rd June 2017, we held the opening ceremony for the 'Micro Reactor Technology Cooperation Laboratory' established at Hebei University of Technology (Tianjin, CN) with our partner Shenzhen E-zheng Technology Co. Ltd.. With Labtrix® Start, KiloFlow® & Protrix® flow reactors available, researchers can develop scalable flow processes & perform valuable training for the next generation!

Jul 2017

CCFlow Consortium Kick-off!

Demo Facility

In July 2017, Chemtrix BV became part of the Austrian Research Promotion Agency's K-Project CCFLOW 'Centre for Continuous Flow Synthesis & Processing', directed by Prof. Oliver Kappe (University of Graz, AT). With a strategic objective to integrate, strengthen & advance existing knowledge in the area of continuous processing / flow chemistry, the project focusses on process simplification, intensification & integration. This industry-academia consortium enables Chemtrix to have a Protrix® silicon carbide flow reactor at CCFLOW!

GramFlow - Product Launch

Product Launch

July 2017 saw the introduction of GramFlow®, our single module glass flow reactor developed for reaction screening & small volume material production. Employing the same integrated heat exchange as KiloFlow®, GramFlow® enables thermally demanding processes to be controlled.

Jun 2018

Fudan University Joint Laboratory

Demo Facility

Fudan University, Chemtrix & E-zheng Joint Laboratory for Continuous Reactor Technology opened in China, enabling local research to be performed using Labtrix® Start, GramFlow® & Protrix® flow reactors.

1st Flow Chemistry Pavilion at ACHEMA 2018

ACHEMA

11-15th June 2018 saw us arrange the first Flow Chemistry Pavilion at ACHEMA. With a five-day exhibition & a one-day dedicated symposium featuring Industrial Case Studies, this event enabled the Flow Chemistry Community to come together & become a destination at this globally renowned tradeshow. The event was a huge success & will be repeated at ACHEMA 21.

Mar 2020

GlobalStars award with Perceptive Engineering!

Project

On March 31st 2020, we entered into a collaboration project with Perceptive Engineering (SG) & a multinational pharmaceutical Company to deliver a solution for the production of high-value / low-volume pharmaceuticals using small-scale, flexible continuous manufacturing. This EUREKA project will allow us to combine our expertise to develop a platform solution applicable to pharmaceutical, agrochemical & specialty chemical production.