News

Read the latest news, case studies & event reports from our Flow Community! Want to stay up to date? Sign-up for our newsletter & a few times per year we will e-mail you interesting articles, developments, up-coming event info!

Researchers at Purdue Center for Cancer Research Develop Innovative, Cost Effective Method to Make Drugs

12 March 2019

As the Food & Drug Administration (FDA) motivates the pharma industry to move away from traditional techniques for drug manufacture towards Continuous processes, David H. Thompson, a Professor in Purdue’s Department of Chemistry & a member of the Purdue University Center for Cancer Research, has written a research paper on the Continuous manufacturing of Lomustine.

Lomustine is prescribed to people with Hodgkin's lymphoma & certain brain cancers. An important feature of the method developed is that it can be used for other pharmaceutical products.

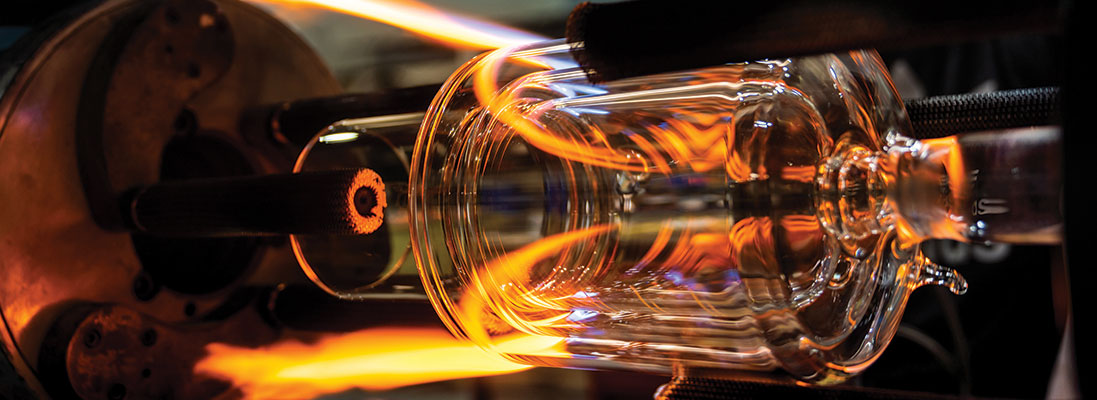

This video shows the use of the Labtrix® S1 in this research.

The FDA put out a statement on February 26 saying the continuous process allows manufacturers to more easily scale operations to meet demand & should help reduce drug shortages. The statement also commented on the fact that continuous manufacturing can provide a more robust, lower cost & diverse supply of drug products.

The goal is to improve manufacturing flexibility, enhance quality & uniformity, while lowering the costs for patients. Continuous manufacturing is an alternative to “batch” production where the drug product is produced continuously through a sequence of coupled flow reactors. Thompson & his Team selected continuous manufacturing for Lomustine because of improved quality monitoring throughout the manufacturing process. In addition, this approach can also reduce production costs by utilising a safer & smaller production facility.

Do you want to learn more about this topic? link

Do you want to know more about the Labtrix S1 shown in the video & used in the research? link

We look forward to seeing more developments from Purdue in the future!